Our experience:

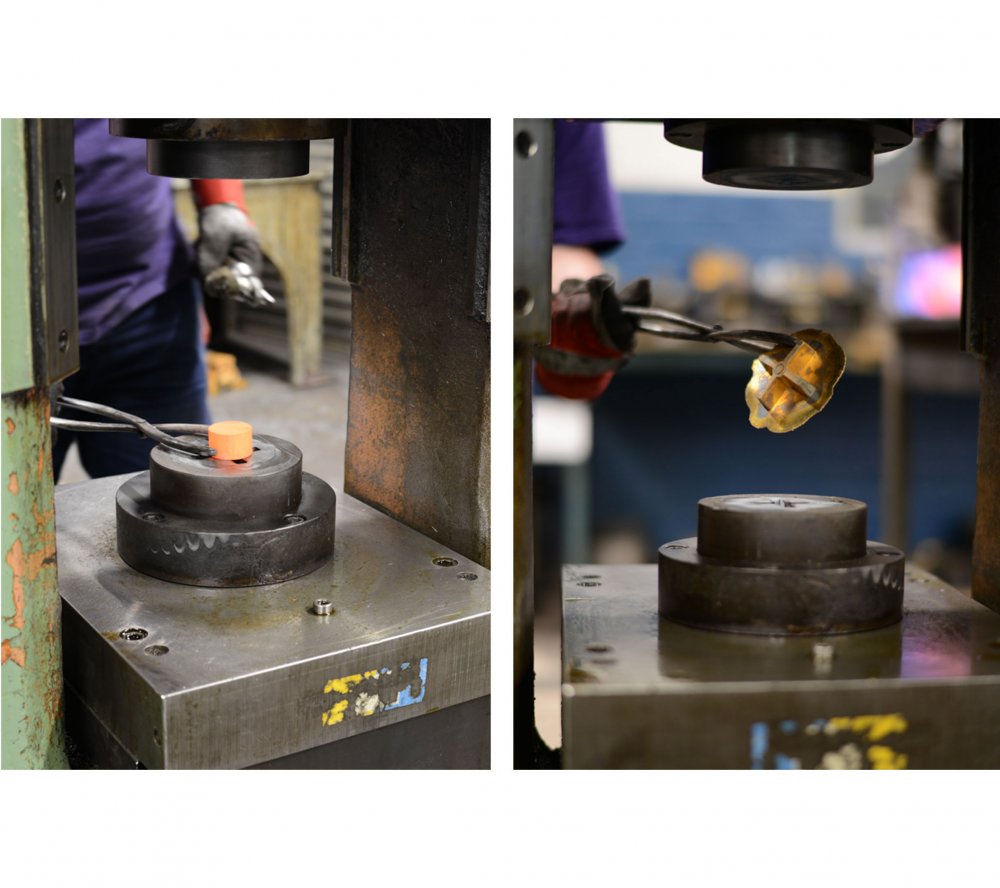

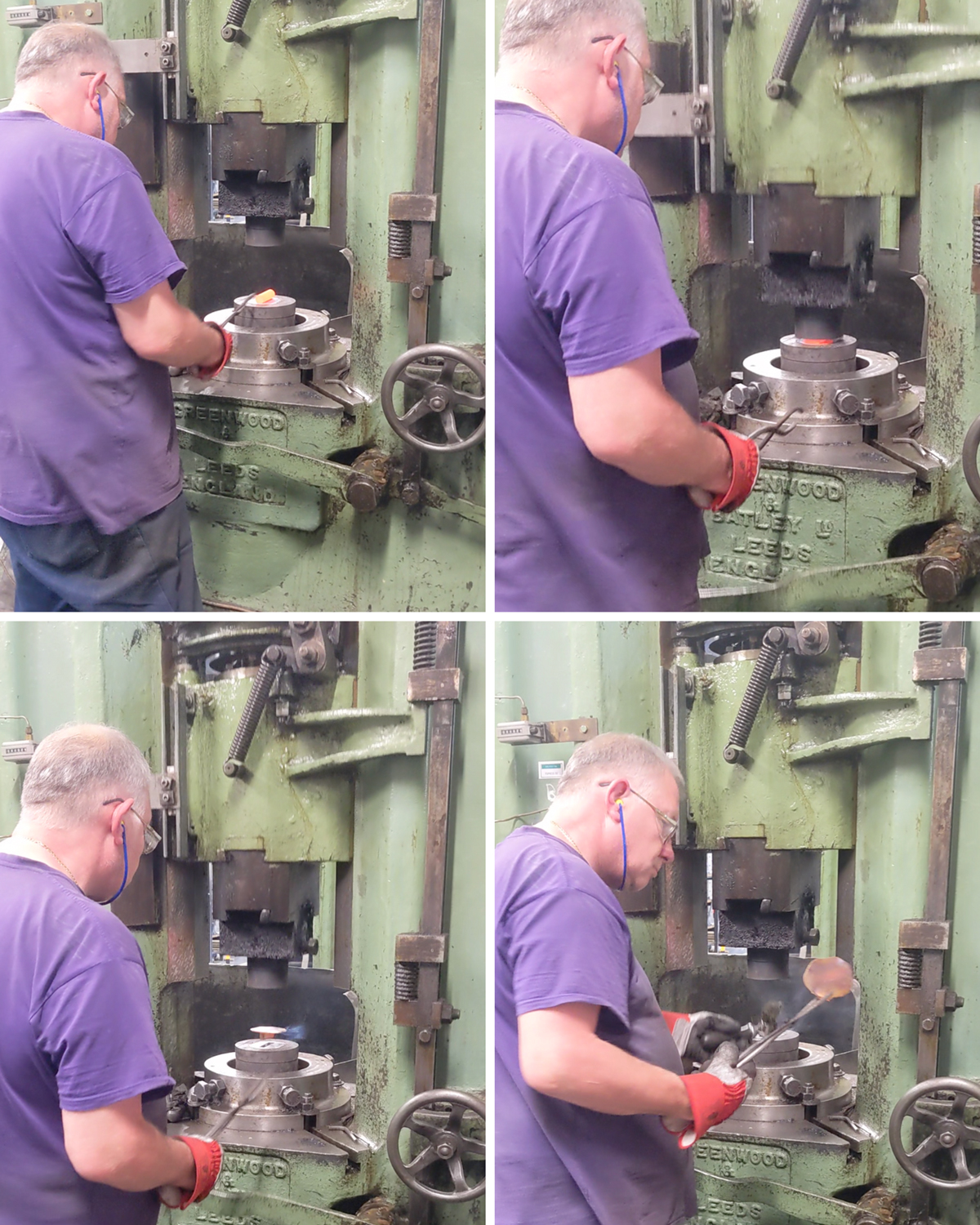

Our team recently visited the Samuel Heath factory in Birmingham, UK, to gain insight into the craftsmanship that goes into each and every product. Renowned for their attention to detail and exceptional durability, Samuel Heath brassware is a popular choice amongst leading hotels.