How and where are your products manufactured?

Samuel Heath use a combination of cutting-edge technology, traditional techniques and time-honored craft in order to create each and every product on-site.

The production is a very human endeavor and the quality is uncompromising at each of the 28 stages that a single component can go through. The phases begin starting with the foundation of all of Samuel Heath products: the purest Northern European metals.

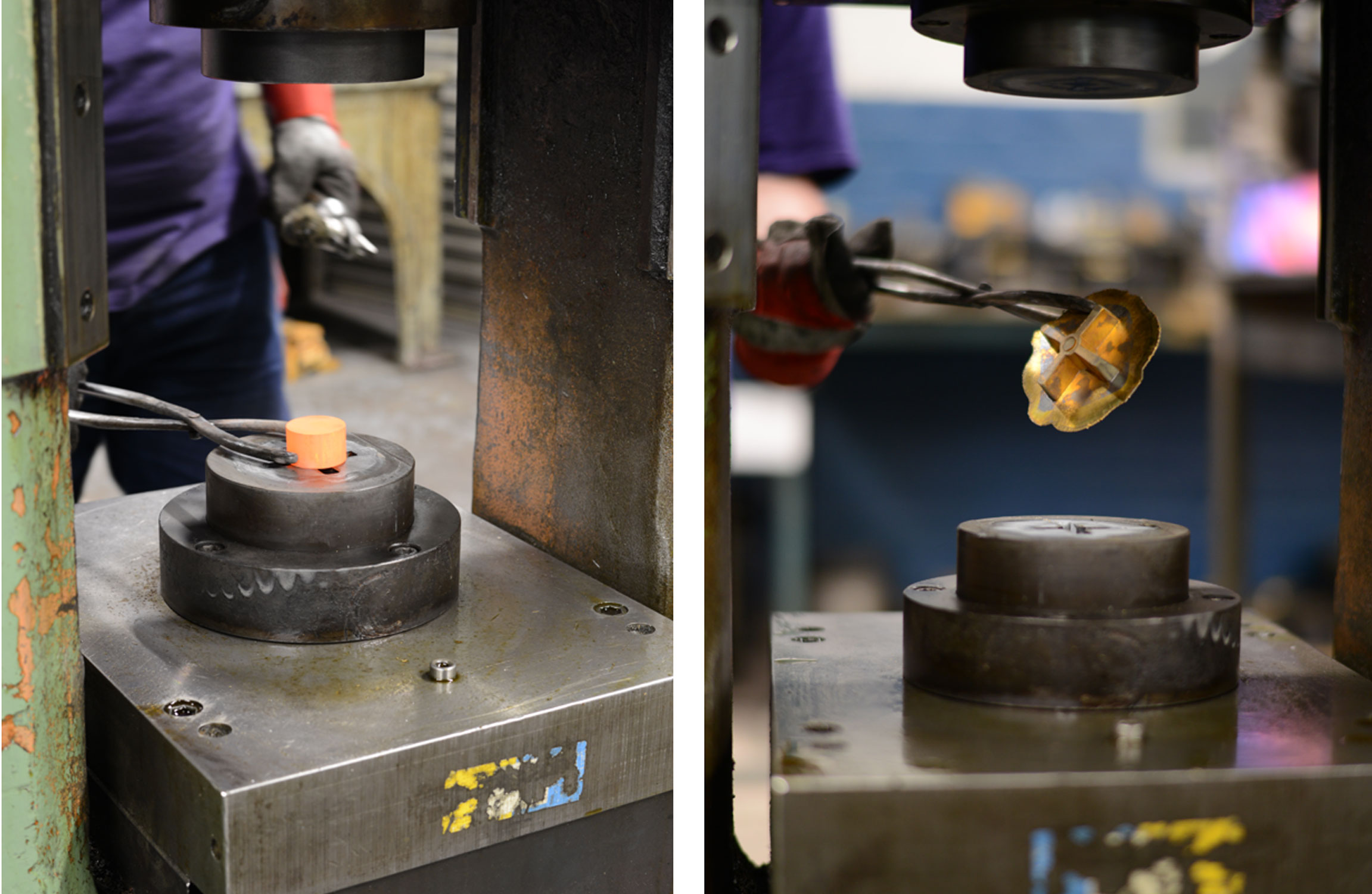

The shaping of the brassware takes place using both modern machinery and traditional techniques. Solid blocks of brass are cut, milled and lathed using advanced CNC machines to adhere to laser-precise detail and specifications. Meanwhile, some components are individually stamped into shape using a traditional Hot Stamp which is heated to 600°C and operated by hand.

Every single part of a fixture, down to the minute components, are hand-polished to achieve a flawless finish so that they are ready for plating. A single spout undergoes a myriad of operations: first, linishing belts with coarse textures create shape and definition. Next, an array of spinning mops with coarse, medium and soft textures are used to manually buff and polish the spout to mirror-shine perfection.

Polishing is crucial in providing a flawless surface for electroplating finishes, so that the brassware can bear its distinguishing features of depth, lustre and durability. The application of finishes takes place within an in-house plating shop via automated and small batch operations, which allows for a wide choice of finishes to be produced within short lead times.